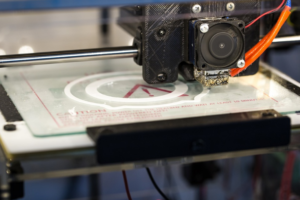

Are you looking for ways to make money with a 3D printer? The advancement of 3D printers took the world with passion, and today, there are so many various applications of 3D printing. Technology is being appropriated more and more by all kinds of business franchises. With the 3D printing’s idle speed and great cost, very rare people saw the technology’s merits but as it is presently far faster and cheaper than before.

Now, starting a 3d printing business (or your choice) is a profitable decision. With 3D printing now a fundamental part of so many diverse industries, the chances to profit from the technology are tremendous. There are various ways you can make money with a 3D printer. 3D printing plastic parts can offer many benefits to your business. In this guide, we’ll take a closer look at some of the main advantages of 3D printing plastics.

Allows Larger Parts

For larger parts, plastic might be an ideal alternative. On the other hand, the truth is that additive manufacturing can be quite expensive when it comes to large quantities.

Offers Cheaper Option

Since plastic is by far the cheapest material on the market today, you can print a fantastic amount of components and assemble them into a huge product. For example, you can print very affordable elements. With HP technology, you are ready to publish many things with inexpensive material. If you are looking for an inexpensive alternative to prototyping, you will find nothing better than 3D printing.

Develops More Efficient Processes

If you want to make changes, all you need is 3D software to modify the version. Despite other processes, custom 3D printing is quite streamlined. If you want to improve your product development processes, you can try this modern external technology.

If you want to make changes, all you need is 3D software to modify the version. Despite other processes, custom 3D printing is quite streamlined. If you want to improve your product development processes, you can try this modern external technology.

Provides Useful Materials

3D printing is one of the best resources for many companies in the market. For example, it is often used to create tools for the healthcare industry. 3D printers can also be used to create 3D models of various organs of the human body. In the automotive industry, this technology has been widely used to create replacement parts for vehicles. Vinyl is a material that can be very valuable for many stages of product development. It is not challenging to mold all types of plastic parts, products, and packaging.

Enables Prototyping With Plastic Materials

For prototyping, plastic could be an ideal alternative. If you are familiar with additive manufacturing, keep in mind that 3D printing offers many prototyping advantages. The main selling point is the fact that it allows you to make crucial customizations economically.